Warehouses in which robots autonomously transport goods, recognise their surroundings and communicate with management systems were, until recently, a futuristic vision. Today, it is a reality that companies are increasingly testing or implementing on an operational scale. The automation of physical processes in logistics is becoming a strategic direction of development – both due to labour shortages and pressure for efficiency. But investments in machinery are followed by a new challenge: managing these machines like IT resources.

A robot is no longer just an execution mechanism. It is also an operating system, a set of sensors, software, APIs, real-time data and the need for updates. It stops being a piece of hardware and becomes an active participant in the digital supply chain. In practice, this means that any company implementing robotics, regardless of industry, becomes an organisation with an IT/OT component – and needs to start thinking like a technology company.

Robot in the warehouse = endpoint IT

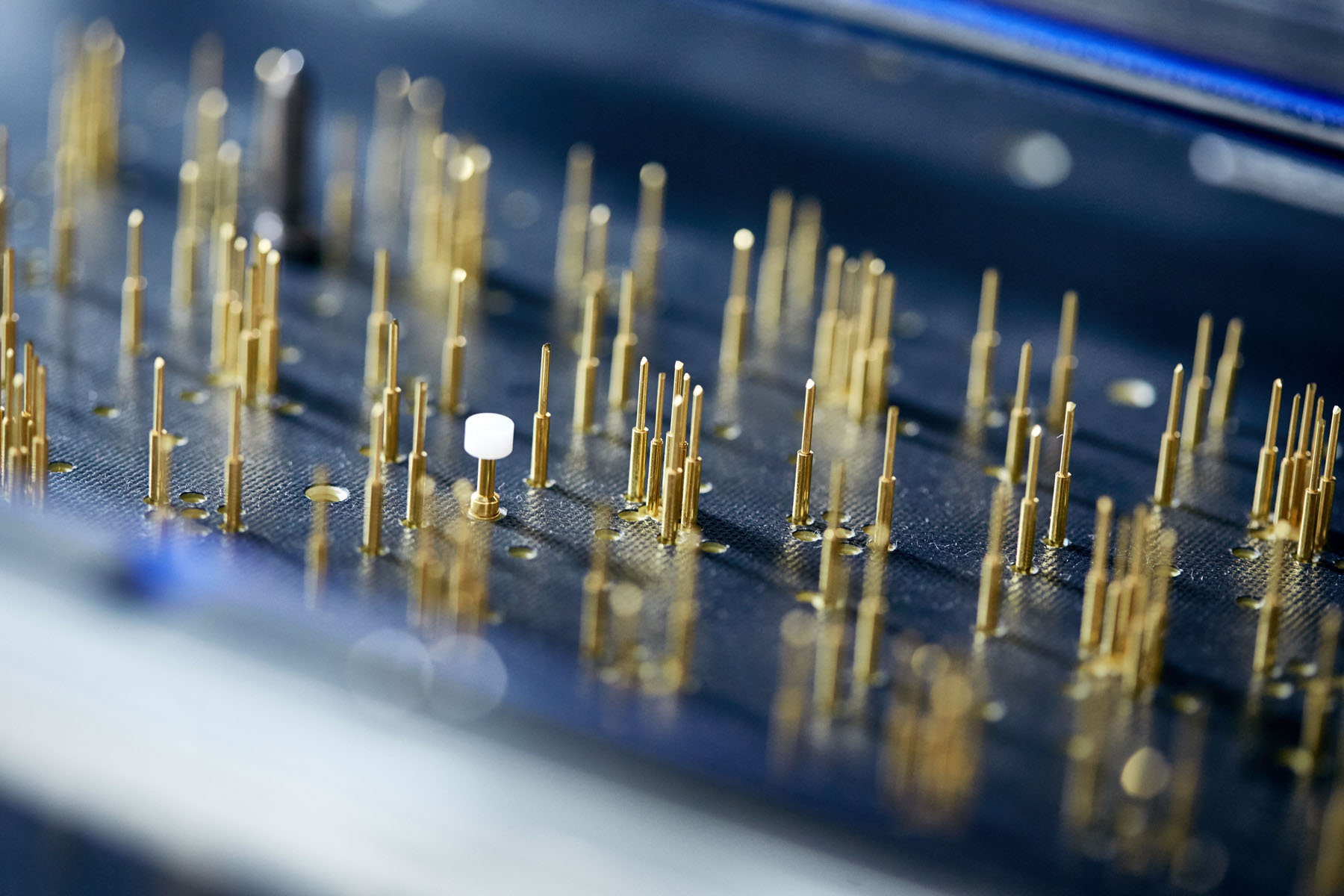

Today’s mobile robots (AMRs) are not just pallet-carrying devices. They are advanced hardware and software platforms: equipped with cameras, lidar, location systems, remote control and the ability to communicate with master systems such as WMS or ERP. Each functions like a mobile node in a network – it exchanges data, is subject to monitoring and, importantly, can be vulnerable to errors and threats.

Unlike classic physical assets, a robot requires maintenance not only mechanically, but also digitally. Regular software updates, patching of security gaps, compatibility tests with other systems – these are all elements familiar from IT infrastructure management. Only that they now happen on the shop floor level.

Convergence of IT and OT in practice

The term IT/OT (Information Technology / Operational Technology) is entering the vocabulary of logistics managers in a new way. Just a few years ago, OT meant PLCs, sensors in production lines or SCADA systems. Today, this world meets modern IT: robots are integrated into business applications and their data analysed in the cloud.

This process creates organisational tensions. Operations departments want efficiency, IT departments want control and security. The question arises: who is responsible for updating the robot? Who ensures that the data from its sensors is compliant with the RODO policy? And who implements patches when vulnerabilities are detected in the robot’s operating system?

In a traditional organisation, no one. Because such roles simply don’t exist yet.

Need for a new layer of governance

Gartner warns that companies investing in robots often lack the organisational structure and knowledge to manage them effectively. As a result, robot fleets are growing faster than the competence of teams. There is a shortage not only of automation engineers, but also of IT architects who understand how to connect warehouse systems to the hardware layer and the network.

This is why there is increasing talk of the need for robotics competence centres – internal units that will act as an integrator of technical, operational and IT knowledge. Not just an R&D department, but also a unit responsible for supplier selection, communication standards, API integration and security policy compliance. Without such a layer, robots in the warehouse will quickly become a source of frustration instead of innovation.

New responsibilities for the IT department

With robotisation, the role of IT departments in logistics companies is also changing. From IT system administrators, they are becoming custodians of the physical digital infrastructure. They must ensure the continuity of control systems, monitor the status of devices, manage access, respond to failures and even prepare backup procedures in the event of network or power failures.

In addition, robots – like any networked device – are an attack vector. Taking control of a fleet of robots can paralyse warehouse operations as effectively as a server failure. For this reason, new security policies, penetration tests and incident response procedures – including the OT environment – are needed.

The robotic warehouse is not just about hardware

Companies implementing robotics often focus on the ROI of their equipment investment. They count how many robots will replace how many workers and after how long they will pay off. Meanwhile, it is worth taking a broader view: every robot is also a source of data that can be used for process optimisation, forecasting and automated decision-making. But for this data to be of value, it needs to be standardised, accessible, integrated with analytical systems – and this is already a task for IT departments.

Robotics is not just about physical automation. It’s about building a digital twin of the warehouse, where every action – pallet movement, stopping time, reaction to an obstacle – becomes data for analysis. In this way, the robot becomes part of a wider digital transformation, rather than just a mechanical performer.

Warehouse automation is not just a change in tools, but a paradigm shift for companies. Robots in logistics require a new approach – one that combines operational and technological competence. In this world, the line between machine and IT system is blurring. And this means that managing a fleet of robots is not a task at the margins of operations – it is the core of a digital supply chain transformation strategy.