In the deep tech industry, and particularly in the advanced semiconductor materials sector, repeat orders are a currency that is often more valuable than the one-off value of a contract. QNA Technology, a Wroclaw-based company that debuted on the WSE’s main floor last year, has just provided the market with proof that its blue quantum dot technology is defending itself in the laboratories of one of the world’s most demanding markets.

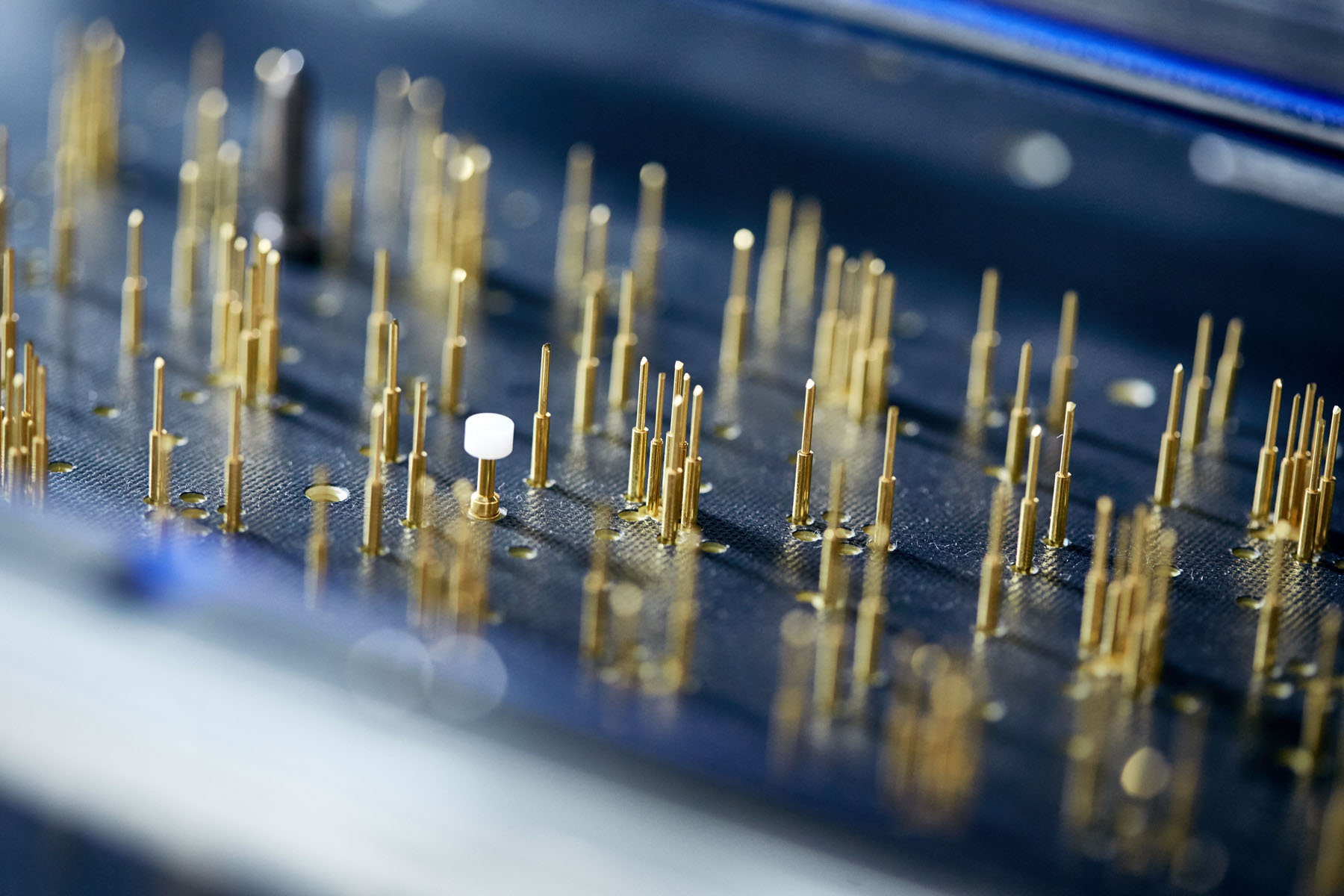

The company has announced the completion of its sixth order for a Japanese chemical company supplying components to global display manufacturers. Although the contract amount of USD 10,000 net may seem modest from a stock market valuation perspective, in the context of the R&D process it is of key importance. It signals that Poland’s PureBlue.dots – quantum dots that emit blue light and are free of heavy metals – have successfully passed the initial testing phases and are being deployed to the increasingly advanced stages of customer validation.

The display market has been struggling with the ‘blue pixel’ problem for years. While red and green quantum dots are already standard, efficient and stable blue emission without the use of toxic cadmium has remained the technological holy grail. QNA Technology’s focus precisely on this slice of the spectrum means that the company is targeting the bottleneck of the entire industry in an attempt to solve a problem faced by the major players.

The regular returns from the Japanese partner suggest that QNA Technology is moving from the experimental phase towards a viable alternative to current solutions. Artur Podhorodecki, the company’s CEO, makes it clear that each subsequent order from the same entity increases the likelihood of moving from pilot sales to full-scale commercialisation. For investors who have been watching the company’s transition from NewConnect to the main market in 2025, this signals the technology’s applicability in a supply chain that historically tends to be airtight to non-Asian entities.

The supply includes material in the form of a colloidal solution, which is standard in the printing processes of modern dies. If the Japanese partner decides to cooperate more widely, the Polish company could become an important link in the production of next-generation displays, fighting for market share in a market so far dominated by giants from Korea and China.